The Department of Mechanical Engineering was established in the year 2008 with an intake of 60 students at under graduate level. In the year of 2013 diploma program was started. We also offer excellent research facility with post graduate(Estd. 2013) and Ph D program (Estd. 2012) aspirants. All the courses are approved by AICTE.

To impart sound knowledge of Mechanical Engineering profession to the next generation of leaders. Create an environment of innovation, research and development. To provide an environment for developing human values through various activities and services.

The Department strives to become recognized in Mechanical Engineering leading to well qualified and competent professionals to serve society through innovation and excellence in teaching and research.

| Category | Course | Intake |

|---|---|---|

| Diploma | Diploma | 60 |

| UG | Bachelor of Engineering(B.E.) | 120 |

| PG | M.Tech | 24 |

| Research | Ph.D. | As per Ph.D. Regulation 2016 |

| S.No. | Name | Qualification | Designation | Photograph |

|---|---|---|---|---|

| 1 |

Mr. Nitin Shukla

Nitin184shukla@gmail.com, nitinshukla@cvru.ac.in |

M.Tech. (Thermal Engineering) |

Assistant Professor & HOD |

|

| 2 |

Dr. Harsh Pandey Harsh25pandey@gmail.com |

M.Tech. (Thermal Engineering) |

Associate professor |

|

| 3 |

Mr. Abhijeet Gupta

Abhijeet.guptabsp01@gmail.com |

M.Tech. (Industrial Engineering) |

Assistant Professor |

|

| 4 |

Mr. Amit Kumar Kachhawaha

Amitkachhawaha7@gmail.com |

M.Tech. (Automation) |

Assistant Professor |

|

| 5 |

Miss. Shivani Sharma er.shivanisharma1990@gmail.com |

M.Tech. (Thermal Engineering) |

Assistant Professor |

|

| 6 |

Mr. Sandeep Kumar Sharma

Saksharma19@gmail.com |

M.Tech. (Thermal Engineering) |

Assistant Professor |

|

| 7 |

Mr. Narendra Kumar Patel

narendra9494@gmail.com |

M.Tech. (Production Engineering) |

Assistant Professor |

|

| 8 |

Mr. Manoj Kumar Dewangan Manojkumar.dewangan@gmail.com |

M.Tech. (Pursuing) |

Assistant Professor |

|

| 9 |

Mrs. Joeeta Mukherjee Joeeta.pari.mukherjee414@gmail.com |

M.Tech. (Pursuing) |

Assistant Professor |

|

This programme is offered by the department of Mechanical Engineering (ME). Diploma Programmed is an AICTE approved 3 years full time diploma programmed of 168 credits divided in 6 semesters. The Diploma program at Dr. C. V. Raman University aims to prepare students for choosing various verticals of mechanical engineering applications. It provides strong foundation for students in core field of design, production and thermal engineering. This enables students to become job readily professionals and helps them to take up supervisory & entrepreneurial roles in future. It also provides scope for higher studies. Students are always motivated to pursue technical programmed, obtaining technical positions in private & public companies & taking up start-ups.

PO1.Engineering Knowledge:Apply the knowledge of Mathematics, Science, Engineering fundamentals, and Mechanical Engineering to the solution of complex engineering problems.

PO2.Problem analysis:Identify, formulate, review research literature, and analyze complex Engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and Engineering sciences.

PO3.Design/development of solutions:Design solutions for complex Engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4.Conduct investigations of complex problems:Use research based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

PO5.Modern tool usage:Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex Engineering activities with an understanding of the limitations.

PO6.The Engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional Engineering practice.

PO7.Environment and sustainability: Understand the impact of the professional Engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable developments.

PO8.Ethics:Apply ethical principles and commit to professional ethics and responsibilities and norms of the Engineering practice.

PO9.Individual and team work:Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10.Communication: Communicate effectively on complex Engineering activities with the Engineering Community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11.Project management and finance:Demonstrate knowledge and understanding of the Engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multi-disciplinary environments.

PO12.Life-long learning:Recognize the need for, and have the preparation and ability to engage in independent and life- long learning in the broadest context of technological change.

PSO1.Apply their knowledge in the domain of Engineering Mechanics, Thermal and Fluid Sciences to solve Engineering problems utilizing advanced technology.

PSO2.Ability to implement the learned principles of Mechanical Engineering to analyze, evaluate and create more advanced Mechanical Systems or Processes.

PSO3.Develop and implement new ideas on product design and development with the help of Modern CAD/CAM tools, while ensuring best manufacturing practices.

This programme is offered by the department of Mechanical Engineering (ME). Mechanical engineers can work on components and equipment for many industries including manufacturing, power, transport, healthcare, solar and water. B.E. Programmed is an AICTE approved 4 years full time Under Graduate degree programmed of 216 credits divided in 8 semesters. The B.E. program at Dr. C. V. Raman University aims to prepare students for choosing various verticals of mechanical engineering applications. It provide strong foundation for students in core field of design, production and thermal engineering. This enables students to become job readily professionals and helps them to take up managerial & entrepreneurial roles in future. It also provides scope for research studies. Students are always motivated to pursue research programmed, obtaining technical positions in private & public companies & taking up start-ups.

PO1.Engineering Knowledge:Apply the knowledge of Mathematics, Science, Engineering fundamentals, and Mechanical Engineering to the solution of complex engineering problems.

PO2.Problem analysis:Identify, formulate, review research literature, and analyze complex Engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and Engineering sciences.

PO3.Design/development of solutions:Design solutions for complex Engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4.Conduct investigations of complex problems:Use research based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

PO5.Modern tool usage:Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex Engineering activities with an understanding of the limitations.

PO6.The Engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional Engineering practice.

PO7.Environment and sustainability: Understand the impact of the professional Engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable developments.

PO8.Ethics:Apply ethical principles and commit to professional ethics and responsibilities and norms of the Engineering practice.

PO9.Individual and team work:Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10.Communication: Communicate effectively on complex Engineering activities with the Engineering Community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11.Project management and finance:Demonstrate knowledge and understanding of the Engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multi-disciplinary environments.

PO12.Life-long learning:Recognize the need for, and have the preparation and ability to engage in independent and life- long learning in the broadest context of technological change.

PSO1.Apply their knowledge in the domain of Engineering Mechanics, Thermal and Fluid Sciences to solve Engineering problems utilizing advanced technology.

PSO2.Ability to implement the learned principles of Mechanical Engineering to analyze, evaluate and create more advanced Mechanical Systems or Processes.

PSO3.Develop and implement new ideas on product design and development with the help of Modern CAD/CAM tools, while ensuring best manufacturing practices.

This programme is offered by the department of Mechanical Engineering (ME). M.Tech. Programme is an AICTE approved 2 years full time Post Graduate degree programme of 72 credits divided in 4 semesters. The M.Tech. Programme at Dr. C. V. Raman University aims to prepare students for choosing various verticals of engineering and technology. It provides strong foundation for students on core engineering and technological areas. This enables students to become job ready professionals and helps them to take up managerial & entrepreneurial roles in future. It also provides scope for research studies. Students are always motivated to pursue research programmes, obtaining managerial positions in private & public sector companies & taking up start-ups.

PO1.Engineering Knowledge:Apply the knowledge of Mathematics, Science, Engineering fundamentals, and Mechanical Engineering to the solution of complex engineering problems.

PO2.Problem analysis:Identify, formulate, review research literature, and analyze complex Engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and Engineering sciences.

PO3.Design/development of solutions:Design solutions for complex Engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4.Conduct investigations of complex problems:Use research based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

PO5.Modern tool usage:Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex Engineering activities with an understanding of the limitations.

PO6.The Engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional Engineering practice.

PO7.Environment and sustainability: Understand the impact of the professional Engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable developments.

PO8.Ethics:Apply ethical principles and commit to professional ethics and responsibilities and norms of the Engineering practice.

PO9.Individual and team work:Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10.Communication: Communicate effectively on complex Engineering activities with the Engineering Community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11.Project management and finance:Demonstrate knowledge and understanding of the Engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multi-disciplinary environments.

PO12.Life-long learning:Recognize the need for, and have the preparation and ability to engage in independent and life- long learning in the broadest context of technological change.

PSO1.Apply their knowledge in the domain of Engineering Mechanics, Thermal and Fluid Sciences to solve Engineering problems utilizing advanced technology.

PSO2.Ability to implement the learned principles of Mechanical Engineering to analyze, evaluate and create more advanced Mechanical Systems or Processes.

PSO3.Develop and implement new ideas on product design and development with the help of Modern CAD/CAM tools, while ensuring best manufacturing practices.

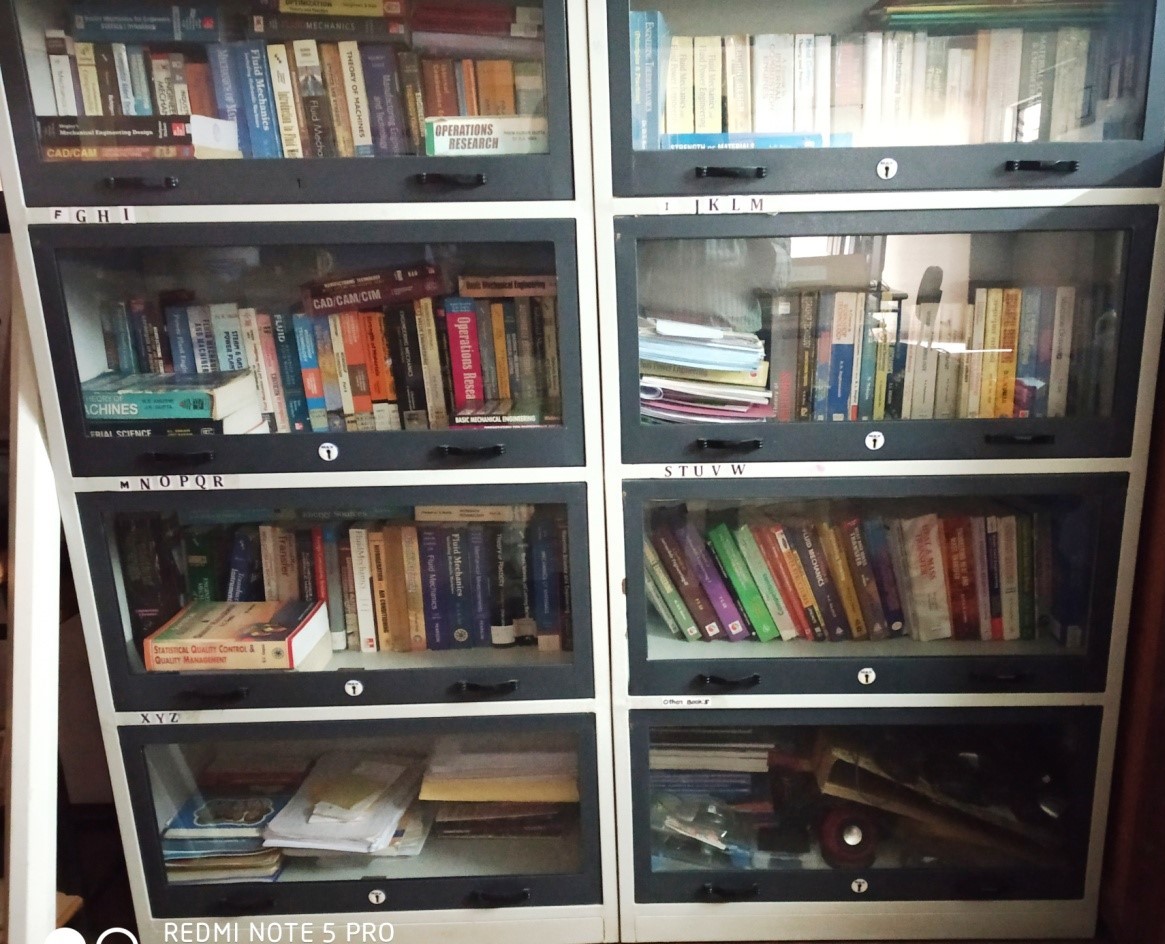

In addition to the Central Library Electronics & Communication Engg. Department have their own Library. This contains important titles and Journals in the respective branches of study. Students and Staff are advised to fully utilize these books and Journals for further enhancement of their subject knowledge books and Journals.

The laboratory is equipped with number of equipment & experimental setups to study the fundamental & applied aspects of the internal combustion (IC) engines. The laboratory facilitates experimental based performance evaluations of a wide variety of IC engines using a wide variety of fuels including the 2nd, 3rd and 4th generation Biofuels.

Automobile Engineering Lab is the investigation and study of manufacturing, designing and operating automobiles such as trucks, buses, cars etc. and their particular engineering subsystems. Automobile Engineering lab additionally offers specialization in alternative fuels, aerodynamics, chassis, emissions, electronics, ergonomics, materials, manufacturing, motorsport, rapid prototyping, vehicle, power train

Heat Transfer laboratory provides fundamental and industrial knowledge about modes of heat transfer, like conduction, convection and radiation, and their application. Heat Transfer Lab consists of the following equipments. Pin Fin Apparatus: This setup is designed to study the heat transfer in a pin fin. It consists of cylindrical fin fitted to the base in rectangular duct. A blower is provided on one side of duct to conduct experiments under forced convection heat transfer mode. Five thermocouples are embedded along the axis of the cylindrical fin at five different locations and one thermocouple placed in the air stream at the exit of the test section to measure the outlet air temperature.

Objectives of this Dynamics of Machines lab are to impart practical knowledge on design and analysis of mechanisms for the specified type of motion in a machine. With the study of rigid bodies motions and forces for the transmission systems, machine kinematics and dynamics can be well understood. Mechanisms form the basis of any machine and it is an assemblage of rigid bodies so that they move upon each other with definite relative motion. Demonstration exercises are provided with wide varieties of transmission element models to understand machine kinematics. Various experiments with governors, gyroscopes, balancing machines and universal vibration facilities are available to understand machine dynamics.

The study of workshop practice acts as the basis for further technical studies. General workshop practices are included in the curriculum in order to provide hands on experience about the use of different engineering materials, tools, equipments and processes that are common in engineering field. The Institute has a modern well established workshop, equipped with various traditional as well as most modern machines and latest tools and instruments. It imparts basic knowledge of various tools and their use in different sections of manufacture such as Fitting, Carpentry, Smithy, Welding etc.

Materials Testing Lab is a range of highly precise and reliable techniques that determine and measure the characteristics of materials, such as mechanical properties, elemental composition, corrosion resistance and the effects of heat treatments.

At Laboratory our material testing services are destructive testing methods that are categorized as mechanical, fracture toughness, fatigue, chemical, corrosion and metallurgical testing. Most material testing is performed on metals, although some services are available for composites, ceramics etc.

It is an introductory lab where flow behaviour, fluid forces and analysis tools are introduced. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as flow through a tube, flow over a flat plate, wind tunnel and viscometer are made available to the students. The lab experiments utilize U-tube manometer and digital manometer. The lab runs closely with the lectures in such a way that experiments support the text covered in the class room.

Refrigeration is the process of removing heat from an enclosed space, or from a substance, and moving it to a place where it is unobjectionable. The primary purpose of refrigeration is lowering the temperature of the enclosed space or substance and then maintaining that lower temperature. The term cooling refers generally to any natural or artificial process by which heat is dissipated. The process of artificially producing extreme cold temperatures is referred to as cryogenics.

Cold is the absence of heat, hence in order to decrease a temperature, one "removes heat", rather than "adding cold." In order to satisfy the Second Law of Thermodynamics, some form of work must be performed to accomplish this. This work is traditionally done by mechanical work but can also be done by magnetism, laser or other means.

Kinematics of Machine lab provides the practical knowledge to the students about various mechanisms & their applications in machineries. This enables student to learn various experiments of different mechanism like cam-follower mechanism, gears, gear train etc. In this way students will understand the practical applications of basic principles in day to day life.

The Engineering Mechanics Laboratory is well equipped with various instruments as per cvru syllabus. This lab is well equipped with Models of truss, column & struts, beams (cantilever and simply supported beam) and three hinged arch. Each working table in the laboratory is well furnished with adequate working space. Engineering Mechanics Lab is primarily dedicated to make the student to understand some basic concepts through experiment. Students perform the practicals under the vigilant guidance and support of one faculty members and one Laboratory In-Charge

Mechanical Measurement & Metrology Laboratory has facility to introduce Linear Measurements, Angular and Taper Measurements, Screw Thread Measurements, Gear Measurements, Measurement of Surface Finish, Straightness, Flatness, Square ness, Parallelism and Machine Tool Tests, Basic Concepts of Measurements, Temperature Measurement and Miscellaneous Measurement.

The Applied thermodynamics laboratory consists of a number of models of steam boilers, steam condensers, Steam turbines, various boiler accessories and mountings. The various models of boiler in lab are Locomotive boiler, La-Mont boiler, Loeffler boiler, Velox boiler.

Laboratory of robotics is the practice of using robots to perform or assist in laboratory tasks. laboratory robots have found applications in diverse industries and sciences, pharmaceutical companies have used them more than any other group.

Advantages of laboratory robotics include high speed, high efficiency, minimal wastage, task reproducibility, task endurance, precision, high productivity, enhanced safety for laboratory personnel, the ability to withstand adverse environmental conditions, and reduced tedium and boredom among laboratory workers who would otherwise perform the tasks.

CAD is used to design, develop and optimize products. CAD (Computer Aided Design) lab is the use of computer software to design and document a product’s design process.

Engineering drawing entails the use of graphical symbols such as points, lines, curves, planes and shapes. Essentially, it gives detailed description about any component in a graphical form. CAD facilitates the manufacturing process by transferring detailed information about a product in an automated form that can be universally interpreted by trained personnel.

| S.No. | Title of Paper | Name of the Author | Department of the Teacher | Name of the Journal | Year of the Publication | ISSN No | Link of the Recognition in UGC Enlisted of the Journals | National/International |

|---|---|---|---|---|---|---|---|---|

| 1 | Parametric Optimization of Electrochemical Machining Process by Particle Swarm Optimization Technique | Nitin Shukla | Mechanical Engineering | SSRG-IJME | 2015 | 2348-8360 | http://www.internationaljournalssrg.org/IJME/2015/Volume2-Issue5/IJME-V2I5P103.pdf | |

| 2 | Parametric Optimization of Electrochemical Grinding Operation by Particle Swarm Optimization Technique | Nitin Shukla | Mechanical Engineering | SSRG-IJME | 2015 | 2348-8360 | http://www.internationaljournalssrg.org/IJME/2015/Volume2-Issue4/IJME-V2I4P101.pdf | |

| 3 | Analysis for Corrosion Monitoring and Prediction of Life of Mild Steel Plate by NDT Technique | Nitin Shukla | Mechanical Engineering | IJSRD | 2016 | 2321-0613 | http://www.jetir.org/view?paper=JETIR1605044 | |

| 4 | Study and Optimization of Graphite Powder Mixed Electric Discharge Machining Of Inconel 718 Alloy | Nitin Shukla | Mechanical Engineering | IJSRD | 2016 | 2321-0613 | http://www.jetir.org/view?paper=JETIR1606023 | |

| 5 | Evaluations of combination of parameters for ARC welding by using hybrid technique | Nitin Shukla | Mechanical Engineering | IJAIR | 2017 | 2278-7844 | http://www.advanceresearchlibrary.com/temp/downloads/ijair/June2017/t25.pdf | |

| 6 | Evaluations of combination of parameters for ARC welding by using RSA technique | Nitin Shukla | Mechanical Engineering | IJAIR | 2017 | 2278-7844 | http://www.advanceresearchlibrary.com/temp/downloads/ijair/June2017/t26.pdf | |

| 7 | PERFORMANCE ASSESSMENT OF MATERIAL PROVIDER’S ORGANIZATION UNDER GREY-MULTI-OBJECTIVE OPTIMIZATION ON THE BASIS OF SIMPLE RATIO ANALYSIS TECHNIQUE | Nitin Shukla | Mechanical Engineering | IJAIR | 2017 | 2278-7844 | http://www.advanceresearchlibrary.com/temp/downloads/ijair/July2017/t8.pdf | |

| 8.9. | APPRAISING VALUE OF MATERIAL PROVIDER’S ORGANIZATION UNDER GREY-REFERENCE POINT APPROACH | Nitin Shukla | Mechanical Engineering | IJAIR | 2017 | 2278-7844 | http://www.advanceresearchlibrary.com/temp/downloads/ijair/July2017/t9.pdf | |

| 10 | OPTIMIZATION OF PROCESS PARAMETERS ON ELECTRIC DISCHARGE MACHINING | Nitin Shukla | Mechanical Engineering | JUSRES | 2018 | 2455-5800 | http://jusres.com/current-issues | |

| 11 | INELLIGENT DSS TOWARDS IDENTIFING THE ILL AND STRONG DRIVERS OF INDIVIDUAL FIRM BY USING FUZZY IN CENTRE METHOD | Raghavendra singh kashyap | Mechanical Engineering | IJEMR | 2017 | 2250-0758 | http://www.ijemr.net/DOC/IntelligentDSSTowardsIdentifyingTheIllAndStrongDriversOfIndividualFirmByUsingFuzzyInCentreMethod.pdf | |

| 12 | PERFORMANCE MEASUREMENT OF INDIVIDUAL MANUFACTURING FIRM UNDER FUZZY PERFORMANCE INDEX MODEL | Raghavendra singh kashyap | Mechanical Engineering | IRJET | 2017 | 2395-0056 | https://www.irjet.net/archives/V4/i7/IRJET-V4I796.pdf | |

| 13 | CNC Machine Tool Evaluation under Mixed Information by FMF Approach | Raghavendra singh kashyap | Mechanical Engineering | IJEMR | 2017 | 2394-6962 | http://www.ijemr.net/DOC/CNCMachineToolEvaluationUnderMixedInformationByFMFApproach.pdf | |

| 14 | COMPARISON ON 1037 CARBON, T-42 H.S.S, CHROME STEEL AND TUNGSTEN CARBIDE USED AS SINGLE POINT CUTTING TOOL RESEARCH METHODOLOGY | Raghavendra singh kashyap | Mechanical Engineering | IJSETR | 2018 | 2278-7798 | http://ijsetr.org/wp-content/uploads/2018/06/IJSETR-VOL-7-ISSUE-6-391-397.pdf | |

| 15 | COMPARISON ON 1037 CARBON, T-42 H.S.S, CHROME STEEL AND TUNGSTEN CARBIDE USED AS SINGLE POINT CUTTING TOOL LITERATURE REVIEW | Raghavendra singh kashyap | Mechanical Engineering | IJSETR | 2018 | 2278-7798 | http://ijsetr.org/wp-content/uploads/2018/06/IJSETR-VOL-7-ISSUE-6-381-390.pdf | |

| 16 | Finite Element Analysis of Fundamental Frequency Responses of the Cylindrical Shell Panel with Cutout | NARENDRA KUMAR PATEL | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_89.pdf | |

| 17 | Flexural Behavior of Laminated Composites Plate under Uncertain Material Properties | NARENDRA KUMAR PATEL | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_83.pdf | |

| 18 | To obtain optimal process parameter for efficient operation of castor oil for lubricant by using Taguchi Method | NARENDRA KUMAR PATEL | Mechanical Engineering | IJSETR | 2016 | 2278-7798 | ||

| 19 | Parametric Evaluation of EDM Using Different Shaped Electrode OnEn32 Steel | NARENDRA KUMAR PATEL | Mechanical Engineering | JETIR | 2016 | 2349-5162 | ||

| 20 | EXPERIMENTAL EXAMINATION OF WELDING PROCESS PARAMETER ON DISSIMILAR MATERIAL BY USING FULL FACTORIAL DESIGN | NARENDRA KUMAR PATEL | Mechanical Engineering | JUSRES | 2017 | 2455-5800 | http://www.jusres.com/article_1507829957.pdf | |

| 21 | QUALITATIVE AND QUALITATIVE MODELING OF RED BRICK MANUFACTURING FIRMS UNDER GREEN AND TRADITIONAL SUPPLY CHAIN USING RPA | NARENDRA KUMAR PATEL | Mechanical Engineering | IJCESR | 2017 | 2394-0697 | http://troindia.in/journal/ijcesr/vol4iss12part5/76-85.pdf | |

| 22 | Failure Resistance and Failure Modes of Bolted Joints between Metal and Thick Composite Materials Plates | NARENDRA KUMAR PATEL | Mechanical Engineering | IJESC | 2016 | 2321-3361 | http://ijesc.org/upload/400d9ecba4233e45c00761c0a5c98f2f.Failure%20Resistance%20and%20Failure%20Modes%20of%20Bolted%20Joints%20between%20Metal%20and%20Thick%20Composite%20Materials%20Plates.pdf | |

| 23 | FLEXURAL FAILURE ANALYSE ON BANANA FIBERS REINFORCED COMPOSITES | HARSH PANDEY | Mechanical Engineering | JOHR | 2015 | 2347-7393 | http://johronline.com/issue/20150427-191840.027.pdf | |

| 24 | OPTIMIZE EFFECT OF TENSILE BEHAVIOUR ON CARBONFIBERS REINFORCED POLYMER MATERIAL | HARSH PANDEY | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150427-192515.172.pdf | |

| 25 | Optimization of machining parameters for electrical discharge machining using RSM | HARSH PANDEY | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_98.pdf | |

| 26 | Experimental Investigation of Machining Parameters for EDM Using D2 tool Steel | HARSH PANDEY | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_99.pdf | |

| 27 | Predict the Surface Finish by using Fuzzy Logic Techniques in ECM Processes | HARSH PANDEY | Mechanical Engineering | IRJET | 2015 | 2395-0072 | https://irjet.net/archives/V2/i3/Irjet-v2i3343.pdf | |

| 28 | Experimental Investigation of Machining Parameter in Electrochemical Machining | HARSH PANDEY | Mechanical Engineering | IJRJET | 2015 | 2395-0056 | https://www.irjet.net/archives/V2/i3/Irjet-v2i3344.pdf | |

| 29 | Experimental Investigation of machining parameters on milling by using full factorial design | HARSH PANDEY | Mechanical Engineering | IRJET | 2015 | 2395-0072 | https://www.irjet.net/archives/V2/i4/Irjet-v2i4178.pdf | |

| 30 | Analysis of Quality and Productivity in Wire Electrical Discharge Machining (WEDM) | HARSH PANDEY | Mechanical Engineering | IRJET | 2015 | https://www.irjet.net/archives/V2/i4/Irjet-v2i4179.pdf | ||

| 31 | ANALYSIS AND OPTIMIZATION OF MACHINING PARAMETERS OF AJM ON COMPOSITE FIBER REINFORCED POLYMER | HARSH PANDEY | Mechanical Engineering | JOHR | 2018 | 2278-2540 | ||

| 32 | EXPERIMENTAL TRAINING OF SHAPE MEMOTY ALLOY FIBRES UNDER COMBINED THERMOMECHANICAL LOADING | HARSH PANDEY | Mechanical Engineering | 2016 | https://www.techno-press.com/journals/sem&subpage=7 | |||

| 33 | SIMULATION OF EFFECTS OF CHANGING SUPPLY AIR VELOCITY AN INDOOR ENVIRONMENT | SHIVANI SHARMA | Mechanical Engineering | IJR | 2016 | 2348-6848 | https://edupediapublications.org/jourmals | |

| 34 | SUPPLY AIR CONDITIONS AND COMFORT IN AIR CONDITIONING OF SPACES | SHIVANI SHARMA | Mechanical Engineering | IJR | 2016 | 2348-6848 | https://edupediapublications.org/jourmals | |

| 35 | PARAMETRIC ANALYSIS OF HEAT SINK USING FINITE ELEMENT VOLUME | SANDEEP KUMAR SHARMA | Mechanical Engineering | IJTE | 2017 | 2395-0250 | http://www.internationaljournalssrg.org/IJTE/2017/Volume3-Issue1/IJTE-V3I1P102.pdf | |

| 36 | PERCEPTION OF CUSTOMER /CONSUMER TOWARDS PURCHASING AND SELLING OF USED PRODUCT THROUGH ONLINE FREE CLASSIFIED ADVERTISEMENT WEBSITE WITH SPECIAL REFERENCE TO RAIPUR CITY (C.G.) | ABHIJEET KUMAR GUPTA | Mechanical Engineering | IRJLTL | 2014 | 0975-282X | ||

| 37 | IMPACT OF RESEARCH IN EDUCATION:TOOL FOR QUALITY EDUCATION AND NEED OF HIGHER EDUCATION WITH SPECIAL REFERENCE TO PT.R.S.S.U. PROFESSORS | ABHIJEET KUMAR GUPTA | Mechanical Engineering | IRJLTL | 2014 | 0975-282X | ||

| 38 | QUALITATIVE AND QUALITATIVE MODELING OF RED BRICK MANUFACTURING FIRMS UNDER GREEN AND TRADITIONAL SUPPLY CHAIN USING FMF | ABHIJEET KUMAR GUPTA | Mechanical Engineering | IJCESR | 2017 | 2394-0697 | http://troindia.in/journal/ijcesr/vol4iss12part5/76-85.pdf | |

| 39 | QUALITATIVE AND QUALITATIVE MODELING OF RED BRICK MANUFACTURING FIRMS UNDER GREEN AND TRADITIONAL SUPPLY CHAIN USING RPA | ABHIJEET KUMAR GUPTA | Mechanical Engineering | IJCESR | 2017 | 2394-0697 | http://troindia.in/journal/ijcesr/vol4iss12part5/5-15.pdf | |

| 40 | PERFORMANCE APPRAISEMENT OF A BRICK INDUSTRY UNDER SUPPLY CHAIN METRICS: VAGUE BASED MODELING | ABHIJEET KUMAR GUPTA | Mechanical Engineering | IJCESR | 2018 | 2394-0697 | http://troindia.in/journal/ijcesr/vol5iss1part5/42-48.pdf | |

| 41 | MULTI-CRITERIA OF DECISION -MAKING APPROACH BY USING FIBER REINFORCED POLYMER IN AJM | ABHIJEET KUMAR GUPTA | Mechanical Engineering | JOSAER | 2018 | 2394-2630 | http://jsaer.com/download/vol-5-iss-12-2018/JSAER2018-05-12-56-61.pdf | |

| 42 | MODELING AND SIMULATION OF END MILLING CUTTER USING FINITE ELEMENT METHOD | ALOK KUMAR PANDEY | Mechanical Engineering | IJRDT | 2018 | 2349-3585 | http://ijsrd.com/Article.php?manuscript=IJSRDV5I110342 | |

| 43 | SIMULATION OF END MILLING CUTTER USING ARTIFICIAL NURAL NETWORK | ALOK KUMAR PANDEY | Mechanical Engineering | IJSRD | 2018 | 2321-0613 | http://www.ijrdt.org/full_paper/27583/19/Modeling-Simulation-of-the-End-Milling-Cutter-by-Using-Finite-Element-Method | |

| 44 | Effect of the moisture on dynamic behaviour of fibre reinforced polymer composites | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_73.pdf | |

| 45 | ANALYSIS OF WELDING STRENGTH BY VARIATION OF VOLTAGE & CURRENT PARAMETER ON MILD STEEL MATERIAL | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2014 | 2347-7393 | https://www.johronline.com/issue/20141206-214912.314.pdf | |

| 46 | FORECASTING OF SPARE PARTS INVENTORY BY EXPONENTIAL METHOD | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150111-025320.162.pdf | |

| 47 | ANALYSIS OF CENTRIFUGAL CASTING DEFECTS ON THEIR MANUFACTURING PARAMETER | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150111-025711.207.pdf | |

| 48 | APPLICATION OF INTELLIGENT TECHNIQUE ON MOBILE ROBOT NAVIGATION | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150111-025935.777.pdf | |

| 49 | APPLICATION OF NEURAL NETWORK TO REDUCE THE MACHINING OPTIMIZATION | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150113-183329.984.pdf | |

| 50 | REDUCE THE TIME SPAN OF JOB SHOP BY SCHEDULING METHOD | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150223-084610.674.pdf | |

| 51 | CRATER WEAR EVALUATION OF TiN COATED TOOL IN MACHINING | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150223-093212.291.pdf | |

| 52 | MAINTENANCE OF ASH HANDLING IN GAS PLANT BY REPLACEMENT OF THRUST BEARING | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150408-105023.960.pdf | |

| 53 | FLEXURAL FAILURE ANALYSE ON BANANA FIBERS REINFORCED POLYMER COMPOSITES | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150427-191840.027.pdf | |

| 54 | OPTIMIZE EFFECT OF TENSILE BEHAVIOUR ON CARBONFIBERS REINFORCED POLYMER MATERIAL | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JOHR | 2015 | 2347-7393 | https://www.johronline.com/issue/20150427-192515.172.pdf | |

| 55 | Study of Different Parameters in CNC Milling Machine Using Composite Material as a Cutting Tool | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | IJESC | 2016 | 2321-3361 | http://ijesc.org/upload/9cb72b16eabfab463189b8e848c23a1a.Study%20of%20Different%20Parameters%20in%20CNC%20Milling%20Machine%20Using%20Composite%20Material%20as%20a%20Cutting%20Tool.pdf | |

| 56 | Effect of the moisture on dynamic behaviour of fibre reinforced polymer composites | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | IJISET | 2016 | 2348-7968 | http://ijiset.com/vol3/v3s6/IJISET_V3_I6_73.pdf | |

| 57 | VIBRATION ANALYSIS ON THE PRODUCTION LINE THROUGH MATLAB | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | IJTRE | 2018 | 2347-4718 | https://www.ijtre.com/images/scripts/2018051117.pdf | |

| 58 | OPTIMIZATION OF TURNING PROCESS PARAMETER ON HARDENED STEEL FOR THREE COMBINED RESPONSES | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JUSRES | 2018 | 2455-5800 | http://jusres.com/download/article/104/1521451706.pdf | |

| 59 | REVIEW ON PRIDICTION PARAMETERS OF TURNING OPERATION ON HARDENED STEEL | AMIT KUMAR KACHHAWAHA | Mechanical Engineering | JUSRES | 2018 | 2455-5800 | http://jusres.com/download/article/103/1519809251.pdf | |

| 60 | Parametric Optimization of Electrochemical Machining Process by Particle Swarm Optimization Technique | Nitin Shukla | Mechanical Engineering | SSRG-IJME | 2015 | 2348-8360 | http://www.internationaljournalssrg.org/IJME/2015/Volume2-Issue5/IJME-V2I5P103.pdf | |

| 61 | Optimization of machining parameter on CNC leadwell of SS304l by using topsis method | Nitin Shukla | Mechanical Engineering | IJRASET | 2019 | 3528-3537 | http://ijraset.com/fileserve.php?FID=22155 | |

| 62 | EXPERIMENTAL INVESTIGATION AND OPTIMIZATION OF MACHINING PARAMETER ON EDM PROCESS OF ZrB2-SiC COMPOSITE USING COMBINATION OF DIFFERENT TOOL (W, NB) BY GREY RELATIONAL ANALYSIS | Nitin Shukla | Mechanical Engineering | IJRASET | 2019 | 3494-3504 | ||

| 63 | MATERIAL SELECTION FOR ELECTRODES TO ENHANCE THE PERFORMANCE OF MICROBIAL FUEL CELL | NARENDRA KUMAR PATEL | MECHANICAL ENGINEERING | IJSETR | 2019 | 186-203 | http://ijsetr.com/IJSETR-VOL-8-ISSUE-5-186-20320200501-85399-19mp6w.pdf | |

| 64 | Parametric Optimization of Process Parameters of EDM for SS304 by Using Design of Experiments Method | NARENDRA KUMAR PATEL | MECHANICAL ENGINEERING | IJSR | 2019 | 56-60 | https://www.semanticscholar.org/paper/Parametric-Optimization-of-Process-Parameters-of-by-Patel-Rathore/8856ffe7dfbcac00871b8c3f219d04d5f50e58e1 |

| S.No. | Name | Title | National/International | Year |

|---|---|---|---|---|

| 1 | Mr. Sumit Bhandari | Parametric Optimization of Electrochemical Machining Process by Particle Swarm Optimization Technique | International | 2015 |

| 2 | Kuldeep Sahu | Analysis for Corrosion Monitoring and Prediction of Life of Mild Steel Plate by NDT Technique | International | 2016 |

| 3 | Vipin Yadav | Study and Optimization of Graphite Powder Mixed Electric Discharge Machining Of Inconel 718 Alloy | International | 2016 |

| 4 | Vivek Sinha | Evaluations of combination of parameters for ARC welding by using hybrid technique | International | 2017 |

| 5 | Nagesh Chandra Sahu | PERFORMANCE ASSESSMENT OF MATERIAL PROVIDER’S ORGANIZATION UNDER GREY-MULTI-OBJECTIVE OPTIMIZATION ON THE BASIS OF SIMPLE RATIO ANALYSIS TECHNIQUE | International | 2017 |

| 6 | Bhuneshwar Kumar Dixena | INELLIGENT DSS TOWARDS IDENTIFING THE ILL AND STRONG DRIVERS OF INDIVIDUAL FIRM BY USING FUZZY IN CENTRE METHOD | International | 2017 |

| 7 | Shashank Tiwari | CNC Machine Tool Evaluation under Mixed Information by FMF Approach | International | 2017 |

| 8 | Arpit Rai | COMPARISON ON 1037 CARBON, T-42 H.S.S, CHROME STEEL AND TUNGSTEN CARBIDE USED AS SINGLE POINT CUTTING TOOL LITERATURE REVIEW | International | 2018 |

| 9 | Akshay Singh Thakur | Finite Element Analysis of Fundamental Frequency Responses of the Cylindrical Shell Panel with Cutout | International | 2016 |

| 10 | Abhishek Kumar Shriwas | Flexural Behavior of Laminated Composites Plate under Uncertain Material Properties | International | 2016 |

| 11 | Nishat Iqbal | QUALITATIVE AND QUALITATIVE MODELING OF RED BRICK MANUFACTURING FIRMS UNDER GREEN AND TRADITIONAL SUPPLY CHAIN USING RPA | International | 2017 |

| 12 | Kewal kalaskar | Failure Resistance and Failure Modes of Bolted Joints between Metal and Thick Composite Materials Plates | International | 2016 |

| 13 | Alok Kumar Rathore | FLEXURAL FAILURE ANALYSE ON BANANA FIBERS REINFORCED COMPOSITES | International | 2015 |

| 14 | Abhishek Kumar Singh | OPTIMIZE EFFECT OF TENSILE BEHAVIOUR ON CARBONFIBERS REINFORCED POLYMER MATERIAL | International | 2015 |

| 15 | Saurabh Sen | Optimization of machining parameters for electrical discharge machining using RSM | International | 2016 |

| S.No. | Name of the Student | Title of Project | Name of the Guide |

|---|---|---|---|

| 1 | Rupesh Adiley | Analysis and Optimization of machining parameter of AJM on composition fibre reinforced polymer | Mr. Abhijeet Gupta |

| 2 | Nishant Iqbal | Quantitative and qualitative modelling of green and traditional supply chain indicator for red brick manufacturing firms | Mr. Abhijeet Gupta |

| 3 | Arpit Rai | COMPARISON ON 1037 CARBON, T-42 H.S.S, CHROME STEEL AND TUNGSTEN CARBIDE USED AS SINGLE POINT CUTTING TOOL LITERATURE REVIEW | Mr. Raghvendra singh Kashyap |

| 4 | Vinay Singh | Optimization of parameter by using of Grey- Taguchi Approach in the context of fused deposit modelling | Mr. Raghvendra singh Kashyap |

| 5 | Anurag Thawait | Investigation of mechanical properties and application possibility of mesa acuminate fibre reinforced | Mr. Piyush Tiwari |

| 6 | Sumit Bhandari | Parametric Optimization of Electrochemical Machining Process by Particle Swarm Optimization Technique | Mr Nitin Shukla |

| 7 | Abhishek Kumar Singh | OPTIMIZE EFFECT OF TENSILE BEHAVIOUR ON CARBONFIBERS REINFORCED POLYMER MATERIAL | Mr. Amit Kacchawaha |

| 8 | Akshay Singh Thakur | Finite Element Analysis of Fundamental Frequency Responses of the Cylindrical Shell Panel with Cutout | NARENDRA KUMAR PATEL |

| 9 | Abhishek Kumar Shriwas | Flexural Behavior of Laminated Composites Plate under Uncertain Material Properties | NARENDRA KUMAR PATEL |

| 10 | Nishat Iqbal | QUALITATIVE AND QUALITATIVE MODELING OF RED BRICK MANUFACTURING FIRMS UNDER GREEN AND TRADITIONAL SUPPLY CHAIN USING RPA | NARENDRA KUMAR PATEL |

| 11 | Kewal kalaskar | Failure Resistance and Failure Modes of Bolted Joints between Metal and Thick Composite Materials Plates | NARENDRA KUMAR PATEL |

| 12 | Alok Kumar Rathore | FLEXURAL FAILURE ANALYSE ON BANANA FIBERS REINFORCED COMPOSITES | HARSH PANDEY |

| 13 | Abhishek Kumar Singh | OPTIMIZE EFFECT OF TENSILE BEHAVIOUR ON CARBONFIBERS REINFORCED POLYMER MATERIAL | HARSH PANDEY |

| 14 | Saurabh Sen | Optimization of machining parameters for electrical discharge machining using RSM | HARSH PANDEY |

| 15 | Harshwardhan Singh Rathore | Parametric Optimization of Process Parameters of EDM for SS304 by Using Design of Experiments Method | NARENDRA KUMAR PATEL |

| 16 | Prashant Tiwari | MATERIAL SELECTION FOR ELECTRODES TO ENHANCE THE PERFORMANCE OF “MICROBIAL FUEL CELL” | NARENDRA KUMAR PATEL |

| S.NO. | TOPIC | SPEAKER | ORGANIZER | DATE |

|---|---|---|---|---|

| 1 | Two days guest lecture on “ENGINEERING GRAPHICS” | Dr. T.D. Motwani Retired Professor GEC Raipur | MECHANICAL ENGINEERING DEPARTMENT | 25-Sep-2011 and 26-Sep-2011 |

| 2 | Two days guest lecture on “ENGINEERING MECHANICS” | Dr. Arun Arora , Principal Bit Durg | MECHANICAL ENGINEERING DEPARTMENT | 07-Nov-2011 and 08- Nov -2011 |

| 3 | Four days guest lecture on “FLUID MECHANICS” | Dr. T.D. Motwani, Retired Professor GEC Raipur | MECHANICAL ENGINEERING DEPARTMENT | 02- Sep-2012 to 05Sep-2012 |

| 4 | One day guest lecture on “ENGINEERING GRAPHICS” | Mr. Devesh Shrivastav, Assistant Professor Bit Durg | MECHANICAL ENGINEERING DEPARTMENT | 18-Mar-12 |

| 5 | Three days workshop on AUTODESK FUSSION 360 | MR. J Atish Rao, Chief Instructor Autodesk | MECHANICAL ENGINEERING DEPARTMENT | 19 to 21SEP-2016 |

| 6 | One day guest lecture on “EMERGING TECHNOLOGY IN MECHANICAL AND INSTRUMENTATION” | Pro. Venkat Dasigi, IIT Chennai | MECHANICAL ENGINEERING DEPARTMENT | 31st March 2018 |

| 6 | Two days guest lecture on “INTRODUCTION TO ROBOTICS AND APPLICATION”. | Mr. Ankur Jaiswal, GMR Institute of Technology,Rajam Srikakulamn(AP) | MECHANICAL ENGINEERING DEPARTMENT | 15th to 16th April 2019 |

| S.NO. | Name | Name of the Event | Funding Agency/Organization Venue | Date/Duration |

|---|---|---|---|---|

| 1 | NITIN SHUKLA | TWO WEEK ISTE WORKSHOP ON FLUID MECHANICS | CONDUCTED BY INDIAN INSTITUTE OF TECHNOLOGY KARAGPUR | 20TH TO 30TH MAY 2014 |

| ONE WEEK NATIONAL LEVEL WORKSHOP ON RECENT DEVELOPMENT IN RENEVABLE ENENRGY | OP JINDAL UNIVERSITY RAIGARH | 30TH NOV TO 5TH DEC 2015 | ||

| 3 DAYS TRAINING ON " ENTREPREURSHIP DEVELOPMENT PROGRAM" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 7TH TO 9TH MAY 2015 | ||

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22ND JULY 2017 | ||

| EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 | ||

| 2 | NARENDRA KUMAR PATEL | EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 |

| FDP ON “TEACHING LEARNING EVALUATION” | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 2ND TO 7TH JAN 2017 | ||

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22-Jul-17 | ||

| NPTEL ONLINE CERTIFICATION ON “PROCESSING OF POLYMERS AND POLYMER COMPOSITES” | IIT ROORKEE | Jul. –Sept. 2017 (8 week course) | ||

| STTP ON “FRONTIERS IN MECHANICAL ENGINEERING” | IIT BHILAI | 17TH TO 18TH JUNE 2019 | ||

| 2 DAYS WORKSHOP ON “INTRODUCTION TO ROBOTICS” | UPU GOVERNMENT Diploma COLLEGE DURG | 27TH TO 28TH AUG 2019 | ||

| ONE WEEK NATIONAL WORKSHOP ON “RECENT TRENDS IN MECHANICAL ENGINEERING, INFORMATICS AND MANAGEMENT” | NIT RAIPUR | 4th to 8th Feb. 2020 | ||

| 3 | SANDEEP KUMAR SHARMA | 3 DAYS TRAINING ON " ENTREPREURSHIP DEVELOPMENT PROGRAM" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 7TH TO 9TH MAY 2015 |

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22ND JULY 2017 | ||

| EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 | ||

| A REVIEW ON THERMAL ANALYSIS OF A FINNED OR EXTENDED SURFACE ''A STATE OF ART'' | SCOPE COLLEGE OF ENGINEERING , BHOPAL | 26TH TO 28TH FEBRUARY 2016 | ||

| 2 Days Workshop on “Applications of MATLAB Tools and Coding for Mechanical Engineering” | BIT, Durg | 1st to 2nd FEBRUARY 2019 | ||

| 4 | HARSH PANDEY | TWO WEEK ISTE WORKSHOP ON THERMODYNAMICS | CONDUCTED BY INDIAN INSTITUTE OF TECHNOLOGY MUMBAI | 24TH TO 02TH DECEMBER 2013 |

| TWO WEEK ISTE WORKSHOP ON FLUID MECHANICS | CONDUCTED BY INDIAN INSTITUTE OF TECHNOLOGY KARAGPUR | 20TH TO 30TH MAY 2014 | ||

| 3 DAYS TRAINING ON " ENTREPREURSHIP DEVELOPMENT PROGRAM" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 7TH TO 9TH MAY 2015 | ||

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22ND JULY 2017 | ||

| EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 | ||

| 5 | Amit Kumar Kachhawaha | 3 DAYS TRAINING ON " ENTREPREURSHIP DEVELOPMENT PROGRAM" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 7TH TO 9TH MAY 2015 |

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22ND JULY 2017 | ||

| EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 | ||

| National PROGRAM ONTECHNOLOGY ENHANSED LEARNING | NPTEL IIT BOMBAY | 23rd TO 26 JUNE 2016 | ||

| MORDREN TRENDS IN ELECTRICAL AND ELECTRONIC SYSTEM | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 27 TH MARCH 2015 | ||

| VIMARSH | CHOUKSE ENGG.COLLEGE | 12TH TO 13 TH SEPTEMBER 2015 | ||

| EMERGING TREND IN MECHANICAL ENGG. | BHARTI COLLEGE OF ENGG. & TECHNOLOGY DURG | 30TH TO31ST JAN 2015 | ||

| 6 | Manoj kumar Dewangan | 3 DAYS TRAINING ON " ENTREPREURSHIP DEVELOPMENT PROGRAM" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 7TH TO 9TH MAY 2015 |

| ONE DAY NATIONAL SEMINAR ON "CLASSROOM TEACHING" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 22ND JULY 2017 | ||

| EXPERIENTIAL FACULTY DEVELOPMENT PROGRAMME | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | 15TH TO 16TH DEC 2017 | ||

| 6 Days FDP on "Teaching and Learning Methods" | DR. C. V. RAMAN UNIVERSITY, KOTA BILASPUR | |||

| 3 days FDP On "Students Induction Program" | C S V T U Bhilai | 4th to 6th july 2018 | ||

| 2 days Workshop under TEQIP-III on "Research Methodology" | GEC Raipur | 26TH TO 28TH September 2018 | ||

| 3 Days FDP On "Students Induction Program" | Pt. Ravishankar University Raipur | 12th to 14th January 2019 | ||

| 7 Days FDP On "Students Induction Program" | RCET RAIPUR | 31ST MAY TO 6TH JUNE 2019 |

CVRUCG © 2024 | Design & Developed By AISECT Web Center All rights reserved.